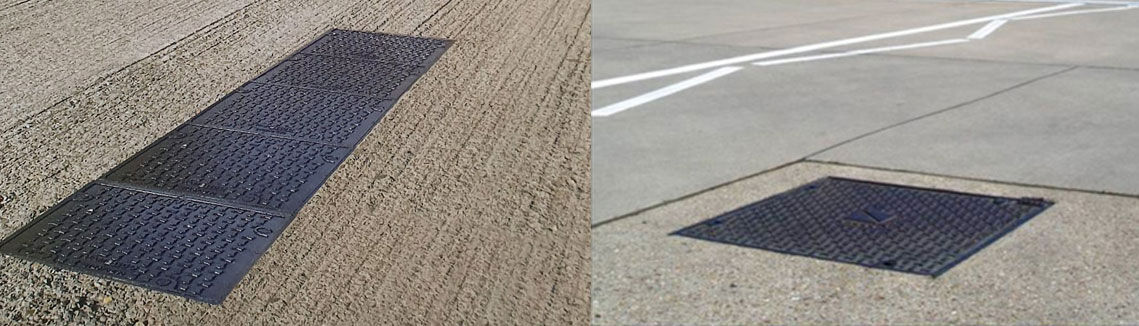

Cover types: Covers are recessed for concrete infill or solid top accordingto specifier preference.

Concrete infill recessed covers: Recessed covers are designed for filling with concrete asspecified in BS EN 124 - C45- 45 N/mm2for a test cube of150mm, or a 40N/mm2for a test cylinder 150mm diameterx 300mm high, using a 10mm coarse aggregate.

Anti-slip surface covers: Concrete infill covers provide a non-slip surface similar to thesurrounding areas. Solid top covers incorporate a raisedlozenge pattern on the surface.

Materials: The components of Gatic covers are manufactured from thefollowing materials:Ductile iron components to BS EN 1563:1997Structural steel sections (removable beams) to BS 4-1:2005

Fine tolerances: The seating faces of Gatic covers and frames are machinedto ensure metal-to-metal contact within 0.25mm tolerance.

Non-rocking: Correctly installed, Gatic covers will be non-rocking under traffic and sealed against ingress of road dirt andother detritus.

Watertight: A film of graphite grease between the contact faces of Gaticunits provides a gas and airtight seal, and a watertight jointunder normal rainwater conditions.

Pressure-tight: Standard single units with locking screws and holding-downbolts are available to withstand upward pressure. Consultour technical department for details.

Easy removal/replacement: The machined underside seating face of Gatic covers allowsthe sliding out of covers for easy removal or replacement.

Operator control: Jack screw operating keys locate positively and securelyinto Gatic covers and are a necessary tool if the inherentcover seal is to be broken effectively and to allow operatormaximum control during operation.

Secure and vandal resistant: Covers are designed to prevent tampering and unauthorised removal. Gatic covers cannot be removed without thecorrect lifting key, so unauthorised removal is virtually impossible. Locking bolts can be fitted to Gatic coverkeyways as an additional security feature.

Ventilation: Ventilation can be provided by fitting four 25mm diameterventilation tubes in recessed covers.

Vibration resistant: To prevent movement of covers in high density trafficconditions, we recommend the use of a factory-fittedvibration-resistant locking system. Can be fitted to recessedcovers only We do not recommend the use of solid top covers in highdensity traffic location

Closed keyways: Gatic cover keyways are closed and fitted with plastic plugsto prevent them from blocking up.

Loadings: All Gatic covers will withstand test load, deflection and maximum deformation criteria specified in BS EN 124 foreach loading category.

Frame bars: Gatic 140mm deep supporting frames incorporate an ‘I’ beam design profile to provide a robust and rigid frame that will withstand the specified loads, without any concrete infill or backfill.

Rigidity: The robust and rigid design of Gatic D400, E600 and F900frames, combined with close manufacturing tolerances,provides a monolithic structure that will withstand thedynamic effects of traffic movement and impact.

Secure support: The clear opening width between supporting frames are atleast 10mm greater than the pit/chamber design to allow forminor deviations in pit construction dimensions.

Beam wallbox: Supporting beams in Gatic Multispan units are easilyremoved with appropriate lifting equipment for access to thetotal chamber area. Beam wallboxes do not project into the chamber opening.

Finishes: Units are coated with a black bituminous solution that actsas a temporary protection during transit, Removablesupporting steelwork is galvanised to BS EN ISO1461:2009. See page 80 for alternative finishes.

Installation: Consignments of Gatic units are accompanied by comprehensive installation instructions

Levelling bolts: All side frame bars and wallboxes are fitted with bolts toassist in the levelling of the unit during installation.

Safety grids: Hinged lift-out galvanised steel safety grids (with padlockfacility if required) can be incorporated into Gatic units. See page 80.

Environmental commitment: Responsibility towards the environment is our primaryconcern. Our customers often now demand products thatare made from recycled and recyclable materials, suppliedby companies with robust environmental policies to reducethe environmental impact of their projects for futuregenerations.

To meet these requirements we have an integrated Quality (BS EN 9001:2008) and Environmental (ISO 14001:2004)Management System which encompasses the design,manufacture and management systems within the company and ensures our commitment to continuous environmentalimprovements regarding the manufacture and design of all our products in the following ways:

• Minimise environmental impact

• Commit organisational resources to energy management

• Reduce energy costs

• Give high priority to energy efficient investments

• Consider life cycle energy costs for all new projects

• Minimise C02emissions year on year

• Use energy from sustainable resources wherever possible

To achieve these goals we have put in place the necessarysystems and controls to meet demanding environmentaltargets and to make sure that these are maintained for thefuture benefit of the environment and our customers alike.

Gatic services: Gatic offers a full support service to specifiers andcontractors, including Computer Aided Design. AutoCADcompatible details of all Gatic products are available. Please consult our technical department for assistance

In view of our commitment to product improvement, wereserve the right to alter designs without notice. Designchanges will not adversely affect the performance or loadingcapability of our products.